CollPlant Biotechnologies and Stratasys have embarked on an innovative pre-clinical study to develop 200cc regenerative breast implants using advanced 3D printing technology. The initiative aims to create implants that promote natural breast tissue growth and completely degrade over time, potentially transforming the breast implant market.

CollPlant Biotechnologies and Stratasys are pioneering a new frontier in regenerative medicine with a pre-clinical study focused on creating 200cc commercial-sized breast implants. The research, which utilizes the Stratasys Origin 3D printer, is designed to test the implants’ efficacy in promoting natural breast tissue growth and ensuring complete degradation over time. Initial results from this study are anticipated by the first half of 2025.

Since their collaboration announcement in April 2023, CollPlant and Stratasys have been working on scaling up the bioprinting process for these innovative implants. CollPlant’s implants are engineered to foster natural tissue regeneration without triggering an immune response, offering a promising alternative to current methods used in reconstructive and aesthetic breast procedures. This technology could significantly impact the $3 billion breast implant market, which primarily relies on silicone implants and autologous fat transfers.

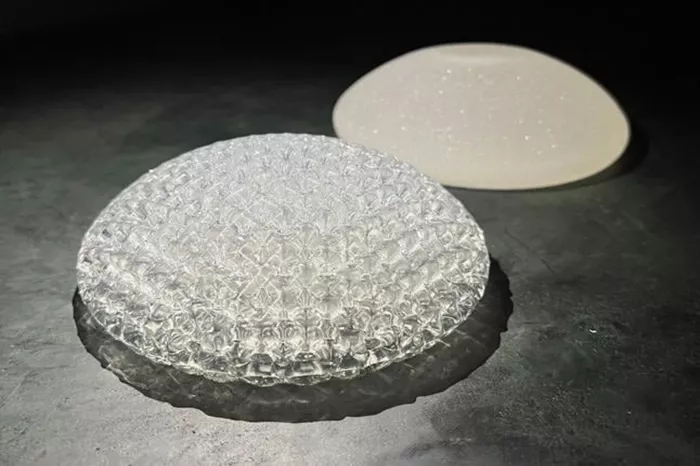

Stratasys has adapted its Origin printer to accommodate the production of these regenerative implants. To date, CollPlant has successfully 3D-printed 200cc implants using this technology. The implants are created with a bioink based on CollPlant’s recombinant human collagen (rhCollagen), which mirrors the type I collagen naturally produced by the human body. This material is noted for its improved biofunctionality, high homogeneity, and reduced risk of immune response compared to other tissue-derived collagens.

CollPlant is also exploring new applications for rhCollagen in tissue regeneration and organ manufacturing. The company’s prior pre-clinical studies demonstrated that their implants promote the development of well-formed connective tissue with blood vessels, indicating effective tissue regeneration. Early signs of biodegradation were observed while maintaining the implant’s original structure.

The safety of these implants has been confirmed, with no adverse tissue reactions reported. Stratasys CEO Dr. Yoav Zeif praised the collaboration, highlighting it as an example of how the company supports innovation through strategic partnerships. CollPlant CEO Yehiel Tal expressed enthusiasm about the progress, noting that the advanced 3D printing technology is expected to streamline the development and production of these regenerative implants, potentially surpassing existing breast augmentation methods.

The medical 3D printing field continues to advance, with Stratasys recently unveiling the J5 Digital Anatomy 3D printer, designed for high-fidelity anatomical modeling. This development underscores the growing importance of 3D printing in medical applications, further supported by recent collaborations like the one between Stratasys and Ricoh, which is evaluating 3D-printed models for orthopedic oncology.

As these technologies evolve, they hold the promise of significantly enhancing patient outcomes and expanding the possibilities in medical treatments and aesthetics.

Related topic:

How Long Do Breast Implants Hurt?

How Often To Replace Saline Breast Implants?